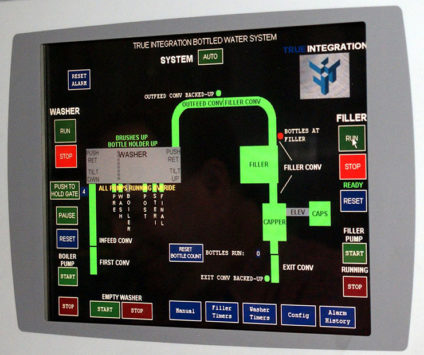

Steelhead Inc. manufacturers water bottling machines and full plant production systems including water treatment systems for the water bottling industry world wide. Bottling equipment solutions include 3, 4 and 5 gallon (19 liter) bottling machines, Reverse Osmosis systems, mineral injection systems, UV filtration and ozone generators.