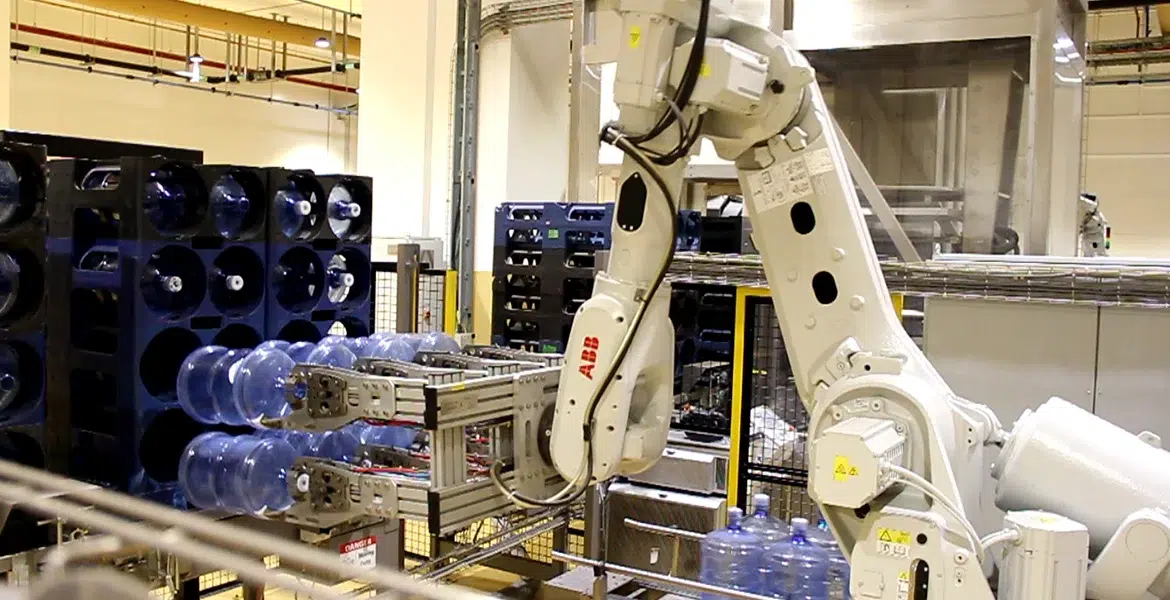

Every second counts in the bottling industry. Keeping production flowing smoothly, safely, and efficiently is crucial to meet customer demand, and robotic rack loaders make it possible. Designed to integrate seamlessly with other bottling equipment, these systems reduce manual labor, prevent bottlenecks, and boost overall line performance. They’re a game-changer for modern bottling operations. At Steelhead Inc., we offer advanced robotic technology that allows companies to achieve these results with reliability and precision.

What Are Robotic Rack Loaders?

Robotic rack loaders are automated systems that handle bottles and racks on a production line. Instead of having workers lift and place heavy bottles, these machines can pick up, move, and place racks of bottles with precision and speed. Many systems also have robotic rack unloaders, which remove empty or filled bottles from racks to continue to streamline the process.

These robotic systems are commonly used in conjunction with a water bottling machine and other bottling equipment to create a fully automated line. They can handle a variety of bottle sizes and types, including 3- or 5-gallon bottles used in home or office water dispensers. By automating repetitive tasks, bottling lines are safer and more productive.

Improve Efficiency with Robotic Rack Loaders

If your bottling line feels like it’s always playing catch-up, robotic rack loaders can help. By handling bottles quickly and accurately, they free up your team and keep your water bottling equipment working smoothly and more efficiently.

1. Increased Throughput

One of the most significant benefits of robotic rack loaders is that they can increase throughput. By moving racks of bottles quickly and consistently, these systems allow a water bottling plant to run at full capacity without disruptions. Many robotic rack loaders can handle hundreds or even thousands of bottles per hour, depending on the model, which is far more than manual labor could achieve.

2. Reduced Downtime

Manual handling of heavy bottles can lead to bottlenecks and production delays. Workers need to take breaks, and mistakes such as dropped bottles can cause spills or damage to the bottling equipment. Robotic rack loaders eliminate these issues by performing repetitive tasks reliably and without fatigue. This reduces downtime and keeps your production line in operation.

3. Improved Safety

Handling full racks of bottles can be physically demanding and increase the risk of workplace injuries. By using robotic rack loaders, businesses can avoid manual lifting and repetitive strain on employees. This not only protects workers but also saves you money on insurance costs and improves workplace morale.

4. Flexibility in Production

Modern robotic rack loaders are highly adaptable. They can be programmed to handle different bottle sizes, rack configurations, and production speeds. When paired with a water bottling machine and other bottling equipment, these systems can switch between product lines in minutes. This flexibility is especially important for businesses that produce multiple beverage products or sizes of bottles, as it allows for a more agile and responsive operation.

5. Integration with Bottling Equipment

Implementing robotic rack loaders into your existing bottling equipment setup is generally straightforward. These systems can be installed at the beginning and end of the line, allowing for automatic loading and unloading of bottles without affecting current processes. Many systems also include sensors and smart controls to synchronize movement with the bottling line for seamless operation.

Smarter Bottling Starts Here

Installing robotic rack loaders into your bottling operation is a smart way to increase efficiency, safety, and productivity. These systems integrate seamlessly with a water bottling machine and other bottling equipment for increased throughput, reduced downtime, improved safety, and consistent quality. Investing in robotic automation can help your business stay competitive and meet growing production demands with ease.

Are you ready to experience the newest technology from Steelhead Inc.? Discover how our solutions can transform your bottling line by requesting a quote or calling 210.628.1066 today.